With my dad in town to lend a hand, we started by building a set of stairs to the second level of the garage, which will be used for storage. Previously I only had a rickety metal ladder. We put hinges on the top of the stairs so they could be hoisted out of the way, to move things in and out more conveniently.

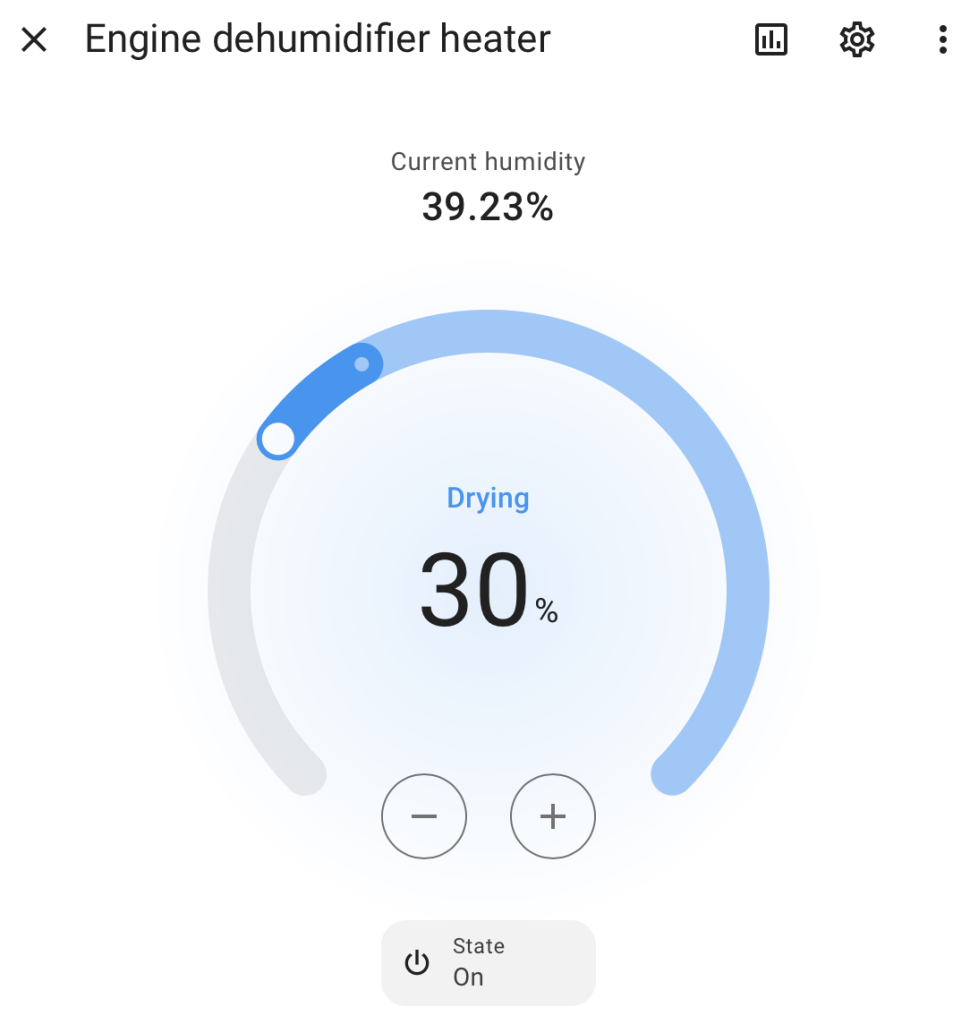

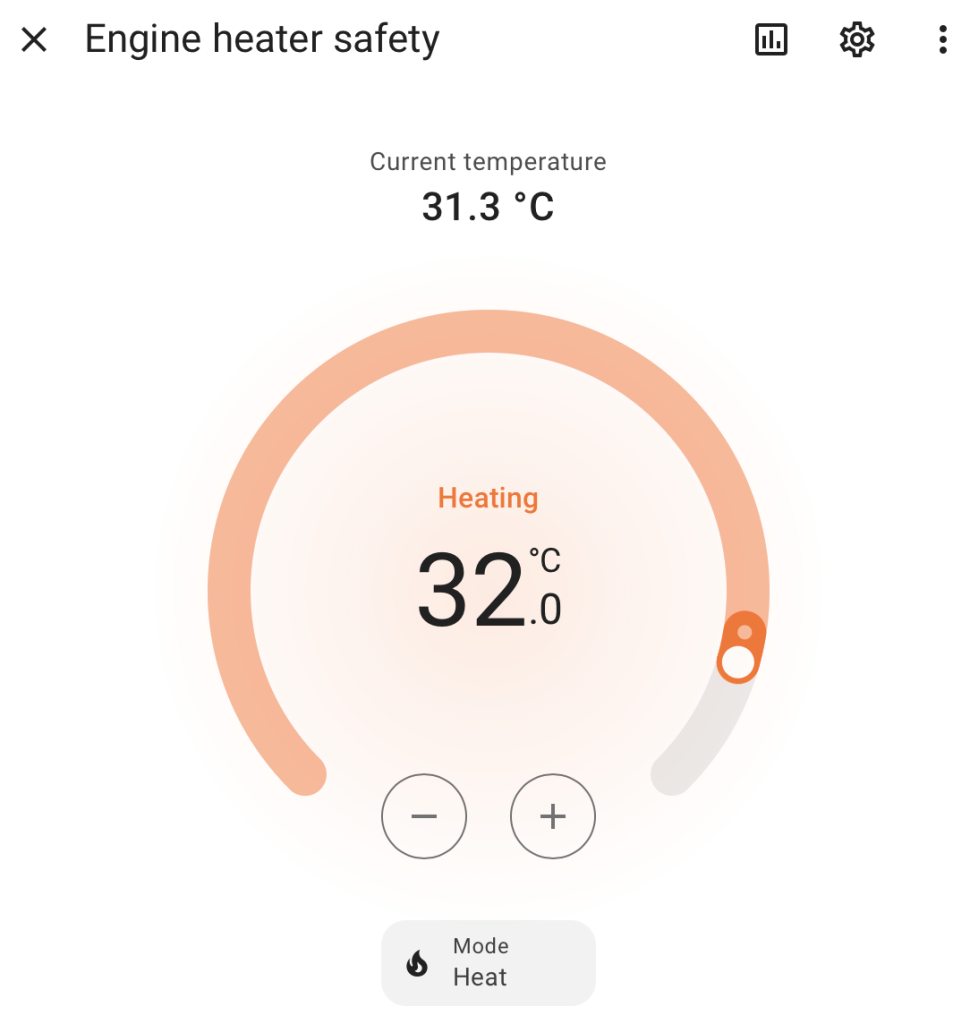

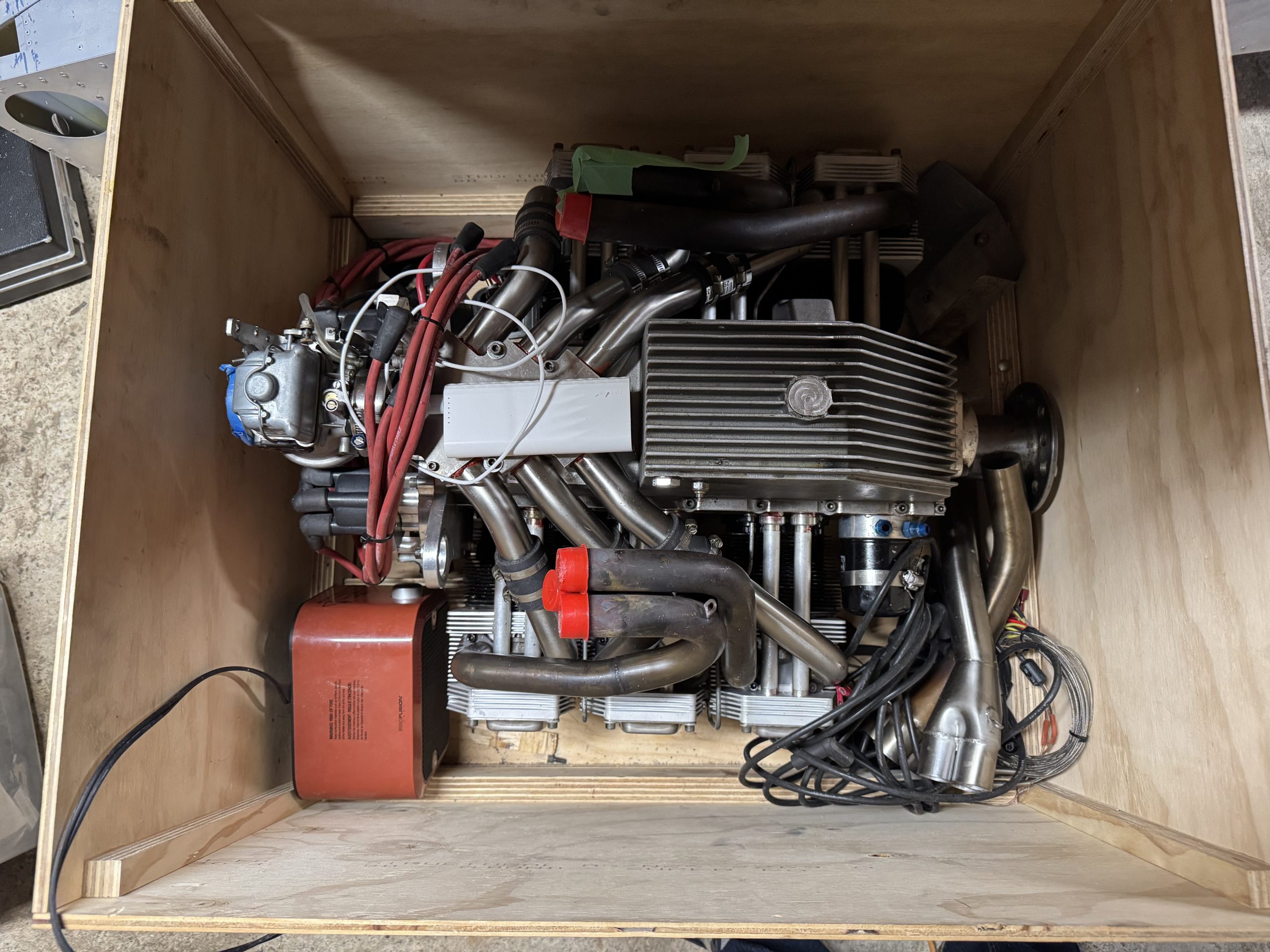

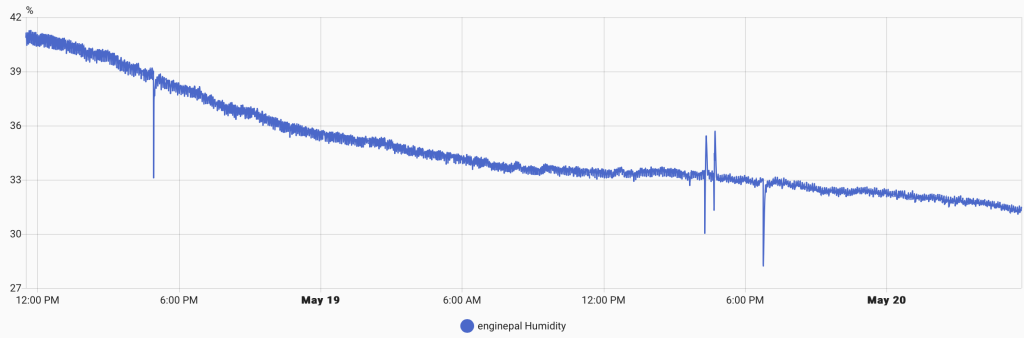

It gets very humid here in the warm season and I was worried about the engine in its crate. I soldered a spare SHT4x to an ESP32-C3 with esphome and added it into Home Assistant. Relative humidity was about 50 %. The addition of a small heater dropped that to below 40 % in a few minutes. I will monitor it over the next few days as it dries. I also added temperature control so the temperature in the crate does not get too high.

Over the next day the humidity dropped to a much more tolerable level, despite heavy rains.

Most of the work so far has been clearing out all the old clutter and dead projects. A newly available storage space about 800 m down the road will allow me to store wood, the abri-tempo, and other stuff I don’t need very often to clear up space for airplane parts. That shed is missing a wall at the moment.

I sent my letter of intent to MD-RA officially starting the build in the eyes of Transport Canada, and paid the first government fee of $125+tax.

Going through the hardware that came with the kit, there seems to be a big mismatch between the hardware I counted and the hardware the plans ask for. There are far too many countersunk driven rivets for example, and I have some bolts that are not in the hardware list at all. There is some hardware missing, including an AN46-7A eye bolt that costs $101.75! Two are needed, good thing I found one.