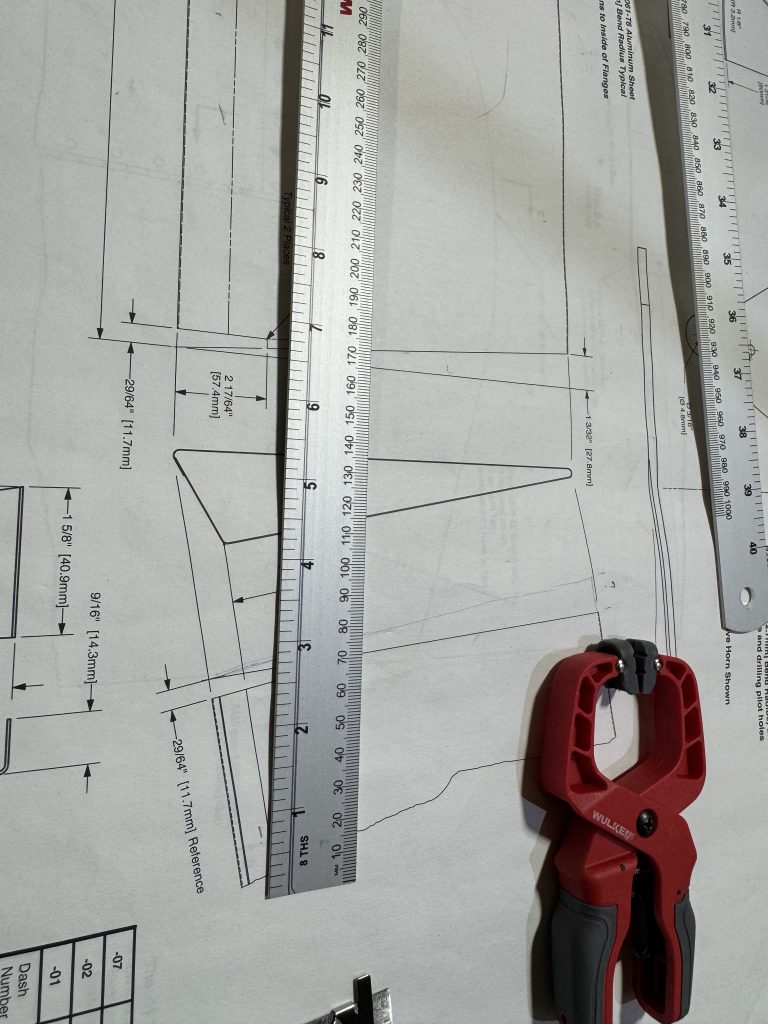

The rudder control horn was already completed, although the 5.2° bend is a little off. Since it is already riveted together and primed I’m just going to use it.

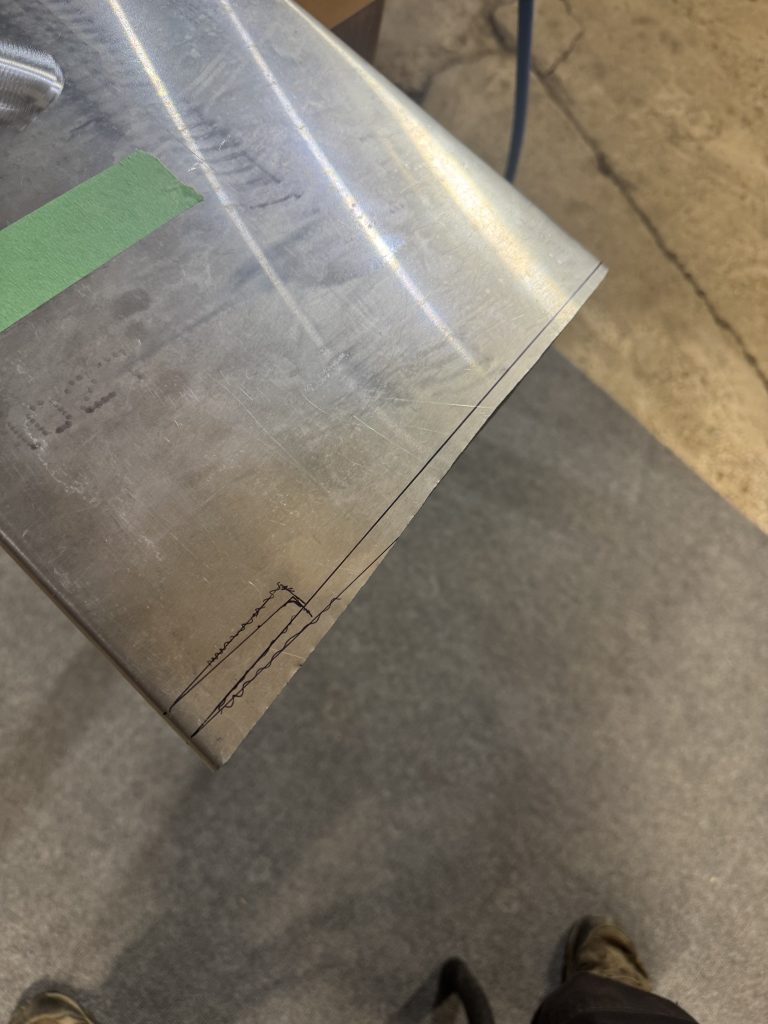

I transferred the end cuts to the control surface stock. Since the stock is a few inches too long, if I mess up I have enough material to try again. Drawing a straight line on a curved surface, then drawing that same line on the opposite surface is a little tricky!

Looks alright I think!

Some of the edges were a little wonky however and I decided to do it again to improve my technique. First, I drew better cut lines using an Ultra-Fine point sharpie.

Then instead of using shears, I made a rough cut on the bandsaw

then got in close with the shears, and used a coarse file to finish and make the edge straight. I think next time I will try a burr.

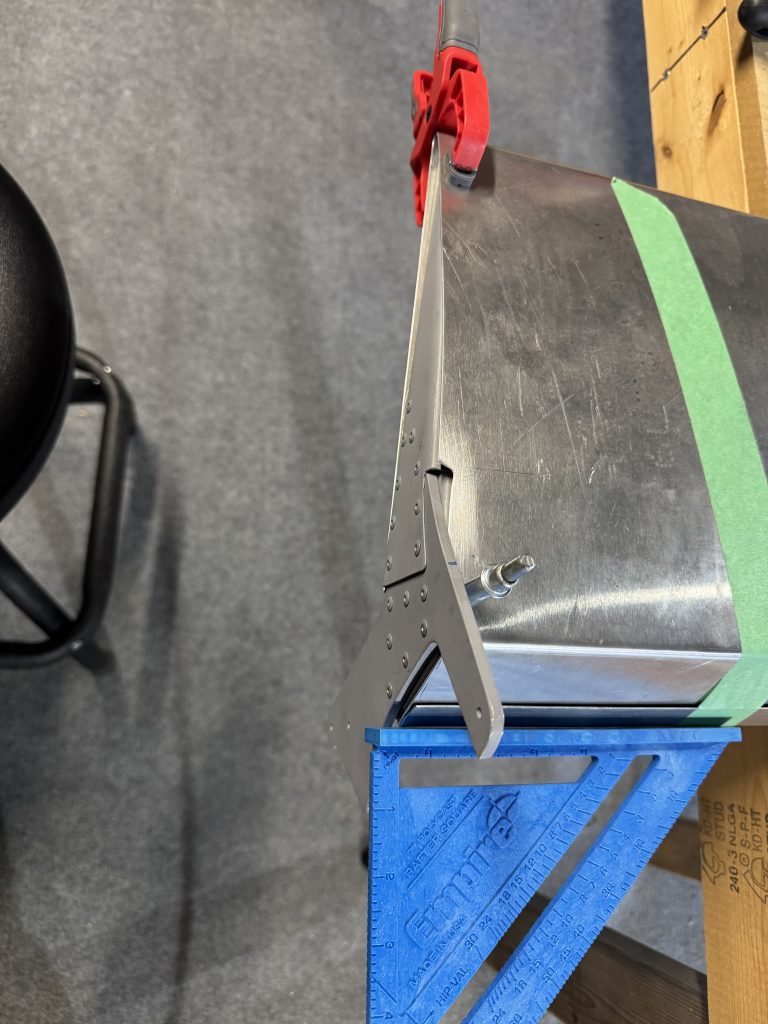

Fitting the control horn straight was a little tricky. I drilled one rivet when it was mostly square, then drilled another after squaring it up.

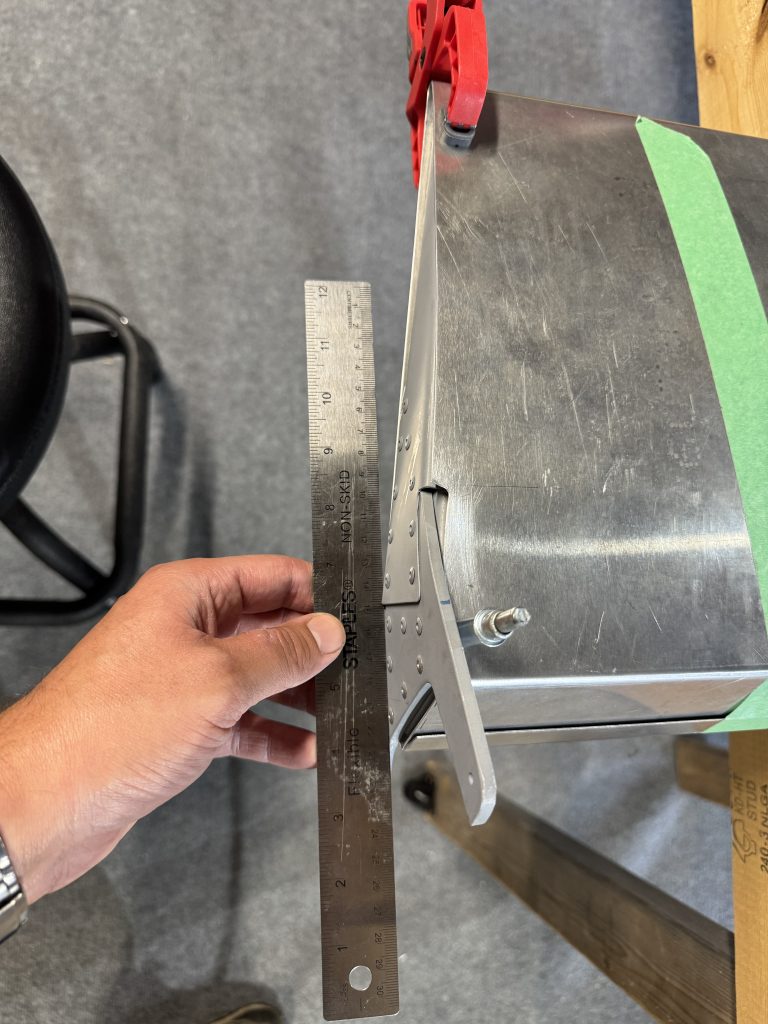

By holding the straightedge and square together at the same time, I could get the horn really straight.

I will have to drill a bunch of rivet lines and hinges. A rivet spacer on Spruce is $90! I’m building an airplane, not a public art installation. With a $3 aluminum ruler from Canac, I drilled holes precisely where they needed to be, and can make a few of them, as Jeff shows on his blog.

My first line was a little off! Turns out it was the clamp that added a bit of tension. Clamping from the end and not the side solved the problem.

A mechanical compass is a requirement in Canada. An Airpath pedestal compass is over $500, plus tax! Someone was selling an illuminated model on eBay for $250, so I snagged it. Unlike electronic instruments, a compass is very unlikely to be outdated by the time I need it.