Now that I have a place to work, I am beginning to assess the parts of the build already done and prepare for the first major milestone. Canadian rules require an inspection of all areas that will be closed-off for the final inspection, and at the same time for the assembly to be as advanced as possible. This complicates planning as pretty much all the metal parts have to be in a mostly-finished state.

The first builder was in USA which does not have this pre-cover inspection requirement, and consequently the airplane was not built with inspection in mind. The second builder, James, was in Canada and had do undo some of the work of the first builder to prepare for the inspection.

The left surface of the vertical stabilizer had its rivets drilled out so the inside could be inspected. Opening it up reveals a job well done. The skin edges were rather rough and I busted my first knuckle on it, so the plane drew first blood on day 1.

The fibreglass tip had been riveted on. Talking to my local MD-RA delegate Mathieu, they are prohibited from using borescopes to perform inspections as it overly complicates matters if a build fails inspection. The tip will have to come off.

There is a spar web and attach angle that should be on the tail. I found the attach angle in a parts box, and found the web already riveted to the fuselage. The lower attach angle was floating around where it will eventually be attached.

Taking apart the horizontal stabilizer, I also found a nice quality of build. There was just one curiosity: the left and right horizontal stabilizer skins had been mis-labelled by a previous builder, with right and left swapped. They had been correctly installed so I am not sure how this could have happened. I will have to keep an eye out for similar errors.

As the horizontal stabilizer tips had been cut to size I test-fit one just for fun. The tips and ribs were correctly labelled left and right. Curiously, I found two complete sets of fibreglass tips and tip ribs in the kit.

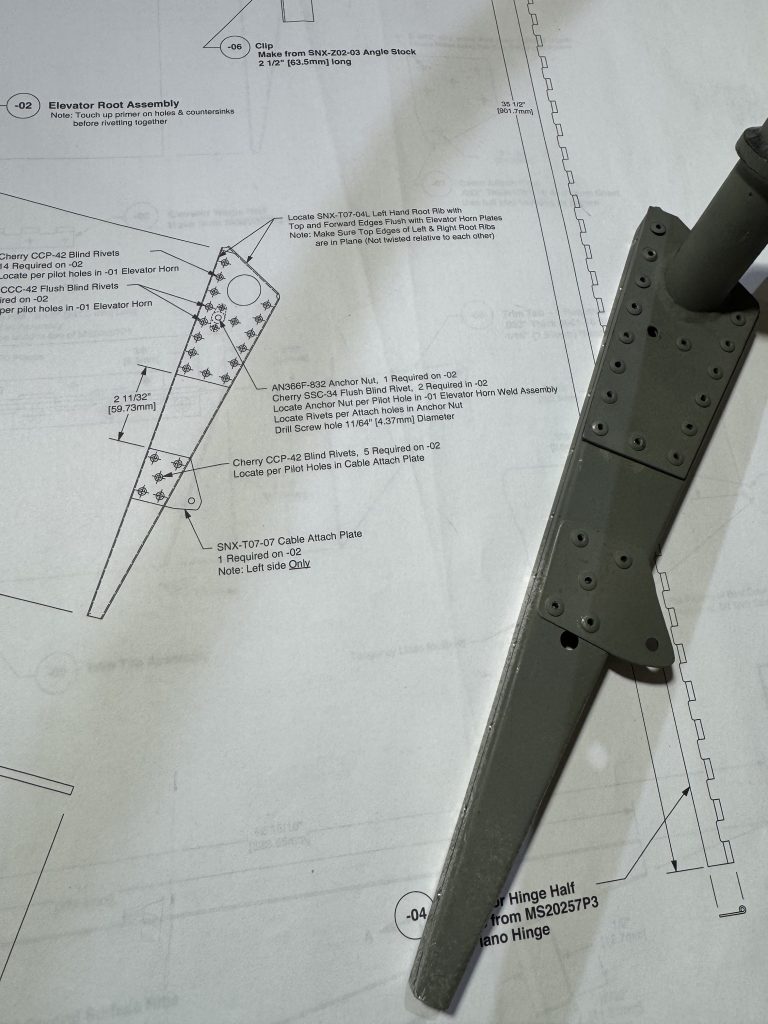

Finally, the trim tab had not been fabricated, and the nutplate had not been attached to the elevator control horn. The trim tab can wait, but the nutplate has to be done before elevator closure.

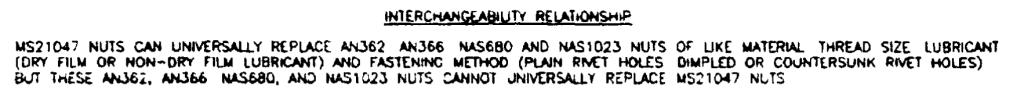

The plans call for an AN366F-832 flush nylock nutplate which Aircraft Spruce doesn’t have; they do have AN366F-832A which is $15.50 at Aircraft Spruce and backordered, and I am not sure what the difference is. The hardware list calls for 4 pieces.

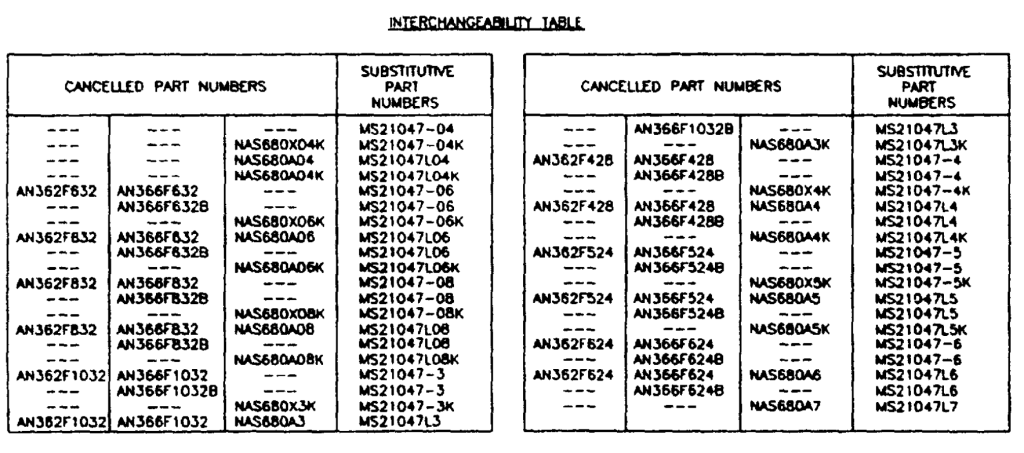

Digging a little deeper, AN366 was superseded by MS21047F and AN366F-832 can be substituted with MS21047-08, which are $1 and stocked (although they only have the variant with dry lube).

These tables were from a document found on EverySpec, which I had never heard of. What a useful resource!

I also have to wonder why the plans ask for a SSC-34 rivet here, which is a non-stainless steel 3/32″ flush pop rivet.

Searching for SSC-34 on Aircraft Spruce produces no results, but they do have the rivet (Part# 04-02338 “CHERRY RIVET SSC-34”). Maybe their search feature does not like the dash.

Last, the local metal shop does not have 0.025″ sheet aluminum, which I will need for the seat pan. Spruce has this of course, so I will be planning for a big order…