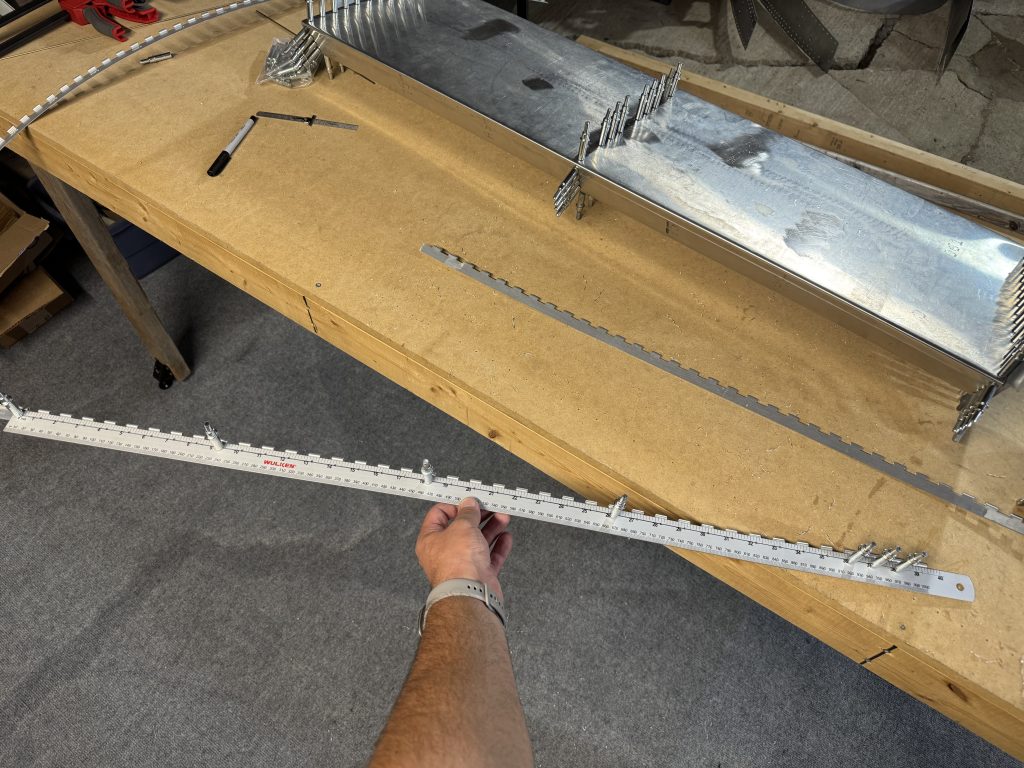

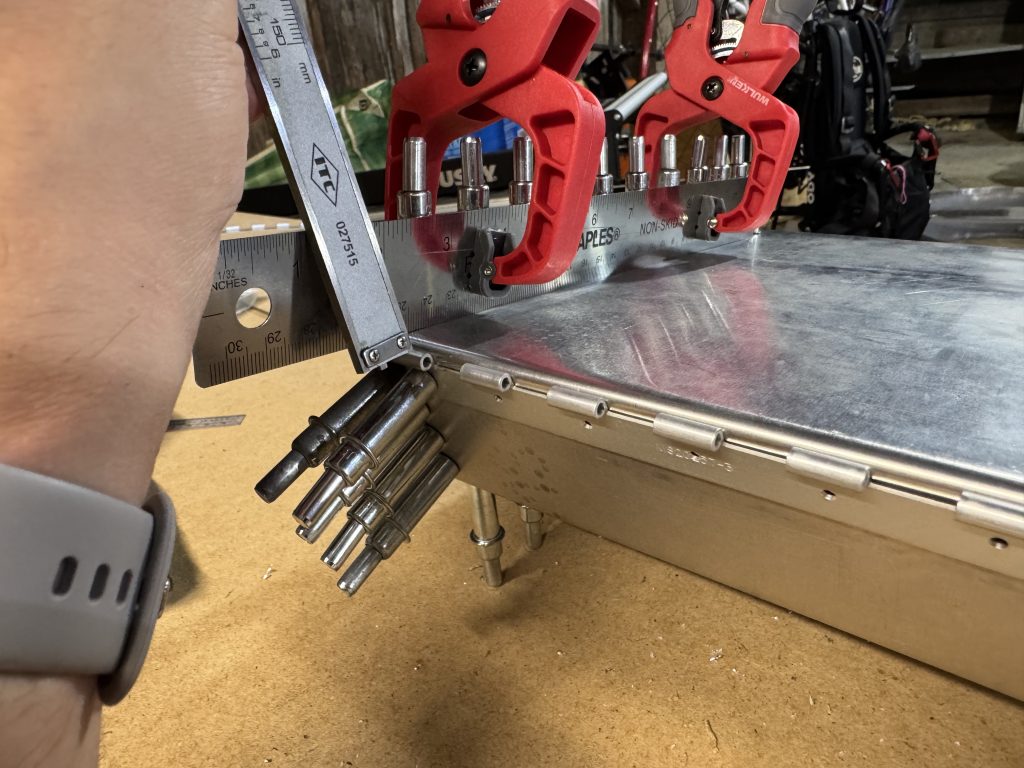

With the arrival of a whole whack of 3/32″ clecos I could finish the rudder, and move on to finishing other parts of the tail.

I went to home depot to get some self-etching primer before riveting the rudder, but it was closed due to flooding. It didn’t even rain that much! I will finish the rudder later.

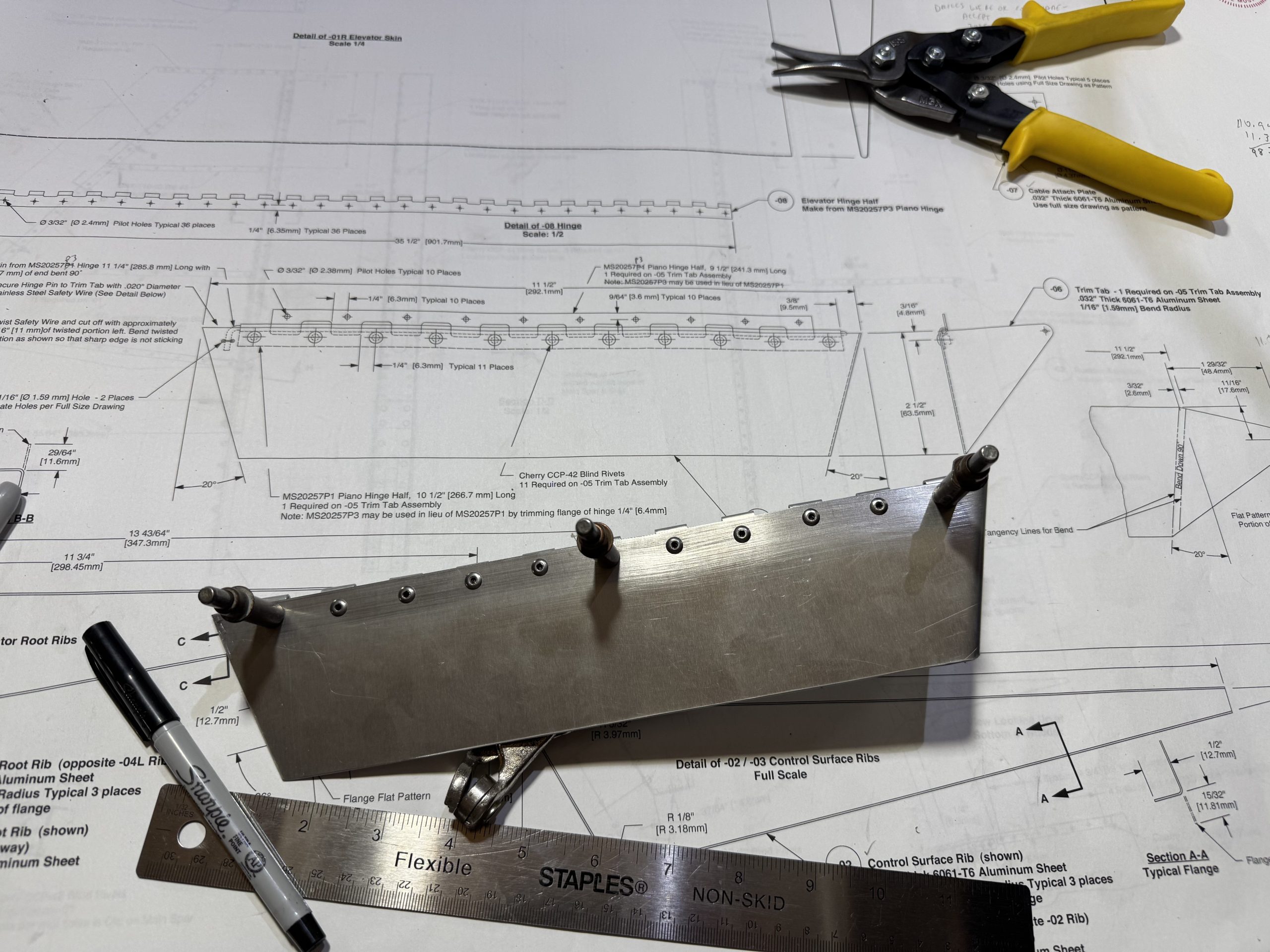

Next, the trim tab.

I made the trim tab in just one night and forgot to take many pictures. It went pretty fast: cut a patch out of a large metal sheet, mark the dimensions on the patch, cut out the profile with snips, perform nice final cuts, mark bends then make the bends, cut and drill the hinge (this hinge also required trimming), drill, updrill, deburr, and rivet, mate the part to the elevator, drill, updrill, deburr, rivet.

I am not very happy with this part. The edges are not very straight which is just cosmetic but still unsatisfying. The arrival of my vixen file should help in the future. The hinge was too close to the trailing edge of the elevator despite adding a small gap to keep it off, so the hinge binds slightly. Also, the hinge on the elevator side is not perfectly flush with the lower surface of the elevator. It will work, but I will wait until the trim system is installed to see if the binding will be a problem.

The wing spar parts that seemed sketchy will be trashed. Out of 3 main webs none are usable, and one of the doublers will be tossed. The rest is good but I will be placing an order at Sonex sometime after Oshkosh. There are also some wing ribs that were trash and I’ll replace them at the same time. I am not sure if I should order extra parts that I will need some time in the distant future just yet – like the jabiru baffle kit. I think I’ll wait and see. Maybe the exchange rate will get better.