With the second floor of the garage cleared out, I could start storing parts up there.

With some space freed up, I can finally see the airplane!

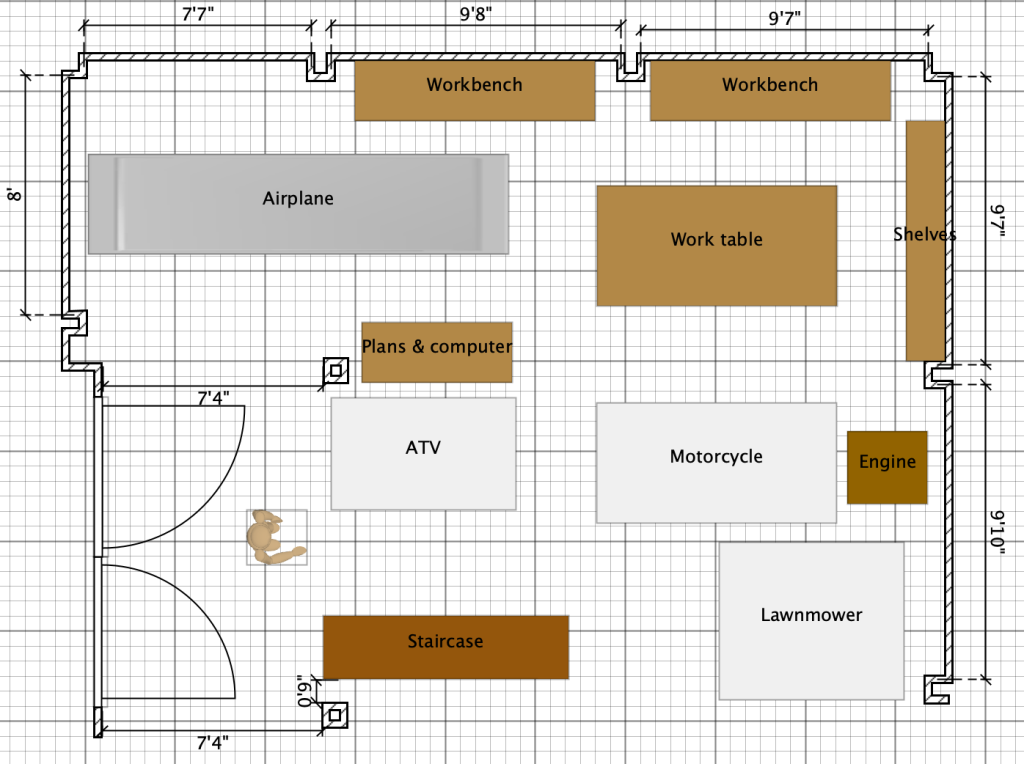

I modelled my half of the garage (Molie gets her half too) in Sweet Home 3D to help me plan it out.

Sonex recommends a 4 x 12′ (1.2 x 3.6 m) work table, but I will try a 4 x 8′ (1.2 x 4.2 m) table for now. The work benches along the walls will hold power tools and pegboard.

The garage is unheated so I picked up this nifty Dantherm VA-M35 military diesel tent heater that is rated at 35 kW, much more power than even the main furnace for the house! It should help keep the work area comfortable even in winter when it hits -25 ℃.

It was just $200! The fan motor was seized however so I removed it and took it to a local electric motor shop. Otherwise it works quite well, and because it was made in Denmark it even has metric hardware.

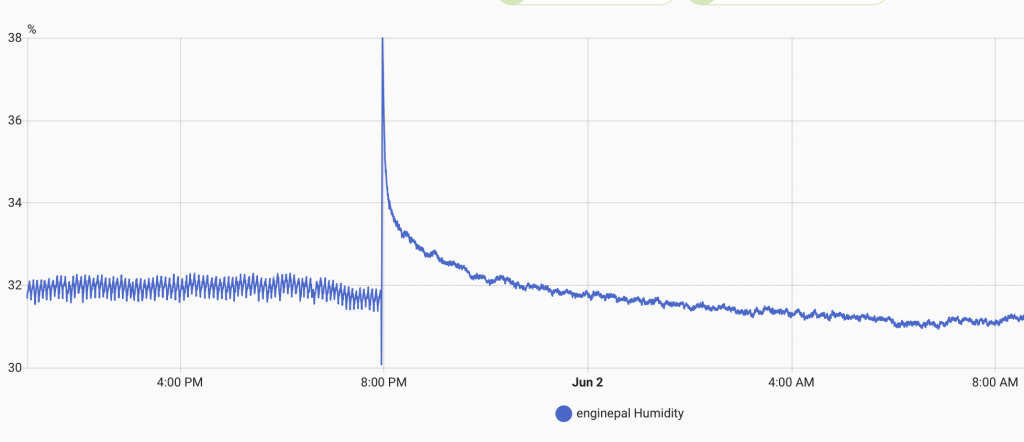

I was unhappy with the “dehumidifier” as the temperature outside increased, so picked up a very cheap peltier dehumidifier. I would not want to use one of these things to dehumidify a room, but it seems to work well for a small box. It has some digital electronics inside and a 5V supply so I should be able to make it controllable with esphome without much effort, but for now it just runs all the time.

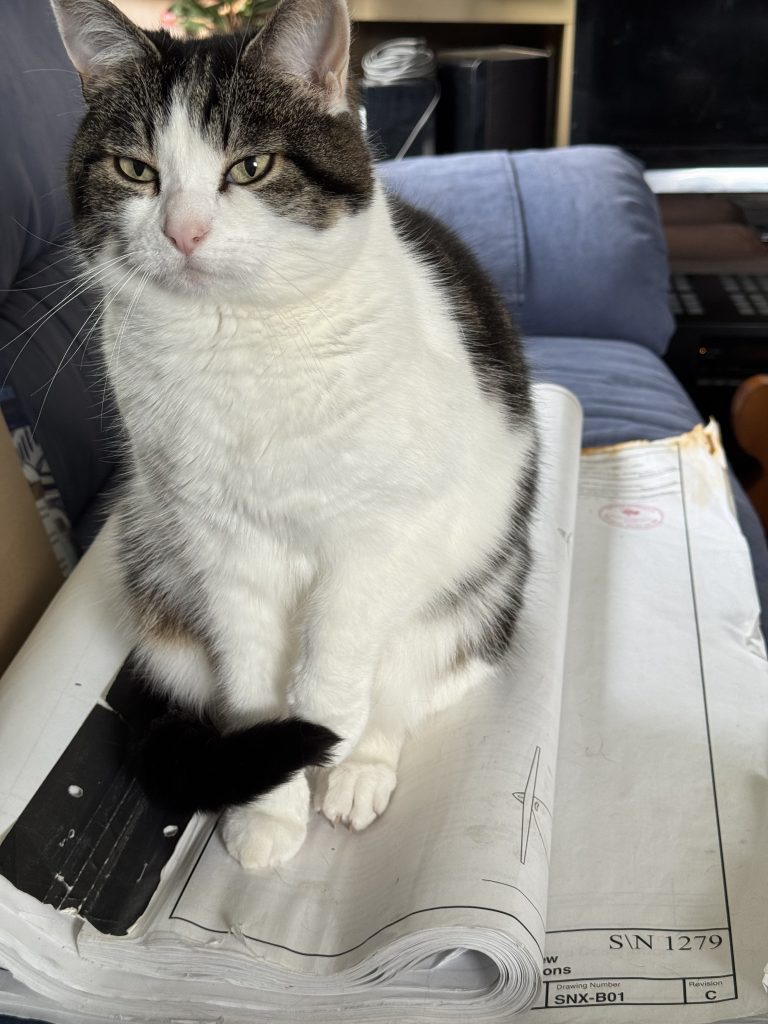

Sifting through the paperwork that came with the plane, I found notes from the previous owner James. He had invested 341 hours over about 2 ¼ years before selling it. Quite a bit of time was spent undoing some of the unsatisfactory work done by the first owner.